Why Does My Breaker Keep Tripping?

By: David Sanders

“Daaaaad! The breaker tripped in the basement again!”

“Not again. That’s the third time this week!”

Sound familiar? It’s no laughing matter when electricity stops working. I can’t think of anyone who likes it. And yet we all deal with it at some point in our lives. But, let me be more constructive.

Today, I’ll help you answer the question, “Why does my breaker keep tripping?”

We’ll discuss:

- things you need to know about breakers and fuses,

- some safe and easy tests you can do to narrow down the cause of an electrical problem,

- some things you can do to help your breakers or fuses keep protecting you,

- and when to call an electrician.

Picture This:

You are minding your own business one evening, living life. You’ve come home after a long day and are doing what you do. Suddenly, the lights go out.

Now, you’re experienced in the ways of the world, so right away you know this could be either a utility problem (meaning it’s a connection issue somewhere upstream of your service meter, and the electric utility company will have to fix it), or it could be your problem (anything beyond the meter and into your home). You take a glance outside, but the windows of the neighboring homes all seem to be lit.

Utility service blackout? Well, nope. But your darkness could still be their problem. Further investigation is needed.

So, you walk into another room and discover, hey, you’re not completely in the dark. There are other rooms throughout the house where the lights still work. Most of the receptacles, still work. The outage appears to be confined to the room you were using. Let’s say it was the living room.

You decide to make one last quick home-owner check to completely rule out the utility. On your way past the laundry area, you check to see if your electric dryer still works. Yes, it’s fine. And its control display seems to light up as well. Okay, by now you are reasonably certain the issue is with your own electrical system, not with the utility company.

[Note: if your dryer or electric range is not working, and especially if none of your breakers have tripped but half the house is still without electricity, this indicates a dropped leg. Or, if your dryer and/or range are the only things working in the entire house, you could have a lost neutral. Either way, a call to the utility company would be prudent; otherwise, an electrician can also determine whose side of the service meter the issue is on.]

You go looking for a tripped breaker. And sure enough, you find a breaker whose handle is in the tripped position, neither on nor off.

[Note: the appearance of a tripped breaker will vary depending on manufacturing design, location conditions, and relative wear. In some cases, none of the breakers may indicate their tripped position visibly, and you’ll have to gently wiggle the handles to see if one feels noticeably looser than the others. Or the breaker may have a small window presenting an orange colored tab inside. In other cases, a tripped circuit will look like someone has turned the breaker completely off.]

You glance at the panel schedule and notice it lists the tripped breaker as “Living Room.” This must be the one. You reach over and press the handle all the way to the OFF position, then turn it all the way in the opposite direction. The handle snaps to ON. Congratulations, you’ve just performed a breaker reset.

What happens next will help narrow down why the breaker tripped in the first place.

Aside from a faulty breaker (which we’ll talk about later), there are two main categories of faults that will trip a breaker, each is a type of overcurrent, which simply means too much current (measured in Amperes or “amps”) passed through the circuit.

The first type of overcurrent, I will call it a “very high current fault.” It is marked by a current that is usually magnitudes greater than that of the Ampere-rating on the breaker. We associate short-circuits (and sometimes, ground faults) with a very high current.

Whatever the cause, there is suddenly not enough resistance in the circuit to keep the current at a manageable level. This could be a hot wire that came loose somewhere and touched another hot or neutral wire, or vice versa. Or, in the case of a ground fault, it could be a hot wire touching a grounded surface or grounding conductor, or vice versa. It could have happened anywhere in the circuit. It may even be a fault in an appliance plugged into the circuit.

If the breaker snaps off again immediately, you probably have a very high current fault. In this case, it is usually best to bring in a qualified electrician who will be able to determine where the problem lies, although there are still a few preliminary tests you can do. We’ll discuss those steps further on.

The other main type of overcurrent that will trip a breaker is called an “overload.” This is one of those “straw that broke the camel’s back” scenarios.

When electric current passes through a conductor, it causes a rise in temperature. The more current that passes through, the higher the temperature climbs. If the circuit is providing current for too many “loads” (appliances, lighting, etc.), the circuit becomes overloaded, and the breaker’s thermal limit is breached.

In normal operating conditions, a breaker's temperature threshold coincides with its amp-rating. So, for a 20-amp breaker, the current should be right around the 20-amp mark when the temperature of the circuit reaches that critical limit and trips the breaker.

Preliminary Tests You Can Do

If you want to narrow the cause of a breaker tripping, here are some safe and easy steps you can take.

If the breaker trips back off instantly, try the following.

- When a breaker trips, search out everything that is no longer working, every receptacle, every light.

- Unplug everything from the dead receptacles.

- Turn the light switches to their off positions. [Note: if some of the dead lights are controlled by three-way switching, change just one of the switches to its opposite position. Then, after resetting the breaker, cycle through all the switches a couple of times to ensure the lights have a chance to be energized.]

- Reset the breaker.

- If the breaker trips immediately again, and you are certain you have unplugged everything on the circuit and de-energized all its lights, call an electrician. Either the breaker is faulty, or it is protecting against a very high current fault.

- If the breaker holds, begin turning on lights one at a time and plugging appliances back in to the circuit.

- Wait a few seconds between each item before turning on the next.

- If one item causes the breaker to trip, you may have found the issue.

Hopefully, the above steps will narrow the problem down to one thing or another. Again, it might be a fault in an appliance, or even in the receptacle it is plugged into. You can try a suspect appliance at another receptacle, and also try a different appliance at a suspect receptacle.

These tests should yield some valuable information and are reasonably safe. If, however, you do not feel comfortable doing them, by all means call in a reputable electrician.

If the breaker holds for a while but eventually trips again, this could indicate that the circuit is being overloaded by too many things connected to it at once. It's a good idea to do the following steps if you are having trouble with breakers tripping due to overloads.

- Again, when the breaker trips, observe which receptacles and lights are affected.

- Take note of which appliances and affected lights were operating at the time of failure.

- Rearrange some of those appliances to different receptacles that were not affected by the breaker tripping.

- Reset the breaker and monitor your results. Hopefully, you’ve fixed the issue.

If nothing else, following the steps above should at least provide some good data to give to an electrician, cutting down on costly troubleshooting time. But in many cases, rearranging appliances and loads more evenly across all of your circuits is a fantastic way to reduce the stress on your electrical system and prolong its lifespan.

How long should my breakers last?

Sadly, electrical equipment does not last forever. Like everything, breakers have a limited life expectancy and will eventually wear out. The Consumer Product Safety Commission (CPSC) is cited as saying a typical breaker under normal conditions will last 30 to 40 years, with some reaching a much higher potential because of better operating conditions. I found a good explanation on Siemen’s website for why there is such a large range for electrical equipment lifespans.

A big factor in the lifespan of your electrical system is something that you can help manage. It has to do with HEAT, which is the silent killer of all mechanical things.

Here are some things to keep in mind about heat and electricity.

- Heat is heat. It doesn’t matter if it’s ambient temperature or heat caused by electrical current, it all adds up to stress on mechanical and electrical parts.

- Loose connections are especially dangerous because heat will build up much faster in a connection that is sparking, even if the sparks are very small. Watch out for intermittent flickering of lights or cord and plug connected appliances that randomly break connection.

- Anytime we can keep electrical equipment cooler (and that even includes the wiring and how and where electricians install it, such as a choice between the attic or a cool basement), we add length to its lifespan.

- You can help your equipment last longer by spreading out the loads you use simultaneously onto different circuits throughout your home and not putting too much on one circuit.

- If you have followed all the suggestions but are still struggling with breakers tripping, a good electrician can help determine what kinds of upgrades would help fix the problems in your system. You may consider adding more circuits to help ease the load on existing ones.

- If you are considering an upgrade or planning to build a new home, before choosing an electrician, ask to know their methods for assuring circuits will be kept as cool as reasonably possible, even in the warmer months.

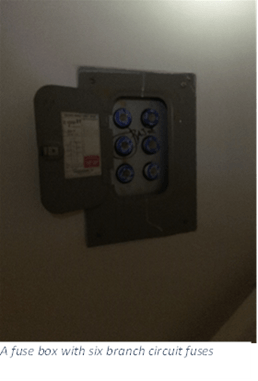

Fuses vs Breakers

Many older homes still have fuse boxes and fuses for their branch circuit overcurrent protection. But does this mean you should worry because your home still uses fuses? Let’s compare fuses and breakers and discuss the benefits of each.

Breakers and fuses both fall under the broader category of Overcurrent Protective Devices (OCPD’s). As we’ve been discussing overcurrents, it makes sense that both types are designed to do just one thing: stop the flow of electricity in the case of an overcurrent.

That sounds like a bad thing when you’re sitting in the dark, but they should only activate when too much electricity starts flowing through a circuit. We need OCPD’s in those dangerous moments when electricity would otherwise become destructive.

A few things to remember about Breakers and Fuses:

- Fuses are inherently reliable because they are so simple. A properly sized fuse is just as safe as a properly sized breaker.

- Fuses, like breakers, are rated in amps. A fuse labeled with the number “20” is good for 20 amps of current before it blows. Likewise, a 15-amp breaker should be imprinted with its rating on the handle and will trip at 15 amps.

- The lower the number of the fuse or breaker rating, the more protection it provides.

- NEVER put a higher rated fuse on a lower rated circuit. It is a dangerous fire hazard.

- An electrician can determine the correct size of fuse or breaker you need, based on the size of the circuit wires and their type of insulation.

In summary, we’ve discussed how breakers and fuses help protect us from dangerous overcurrents that could otherwise result in fire. I’ve explained some safe and simple trouble shooting steps you can take to determine what is causing a breaker to trip. You should now understand the difference between the two main types of overcurrents, and how to tell which kind is likely tripping a breaker. And I’ve listed some recommendations to help you reduce overloading and stresses on your breakers to increase their lifespan.

https://www.youtube.com/channel/UCzEnpEZnLGtuVGyzpeT2Jpg

https://www.facebook.com/Electrician-ED-107527198489309